PICKER heat exchangers are all SHELL-SIDE single fluid flow cycle models (around the tubes) and, depending on the family of exchangers, can feature single, double, triple or quadruple TUBE-SIDE fluid flow cycles (in the tubes).

Depending on the construction materials and the applications in question, the tube bundles in PICKER heat exchangers are connected to their tubesheets by tinning with tin and lead or tin and silver.

The tube bundles in PICKER heat exchangers are smooth and rectilinear (there are no U tubes), with a standard outside diameter of 6 or 8mm.

ESCAPE INDICATOR

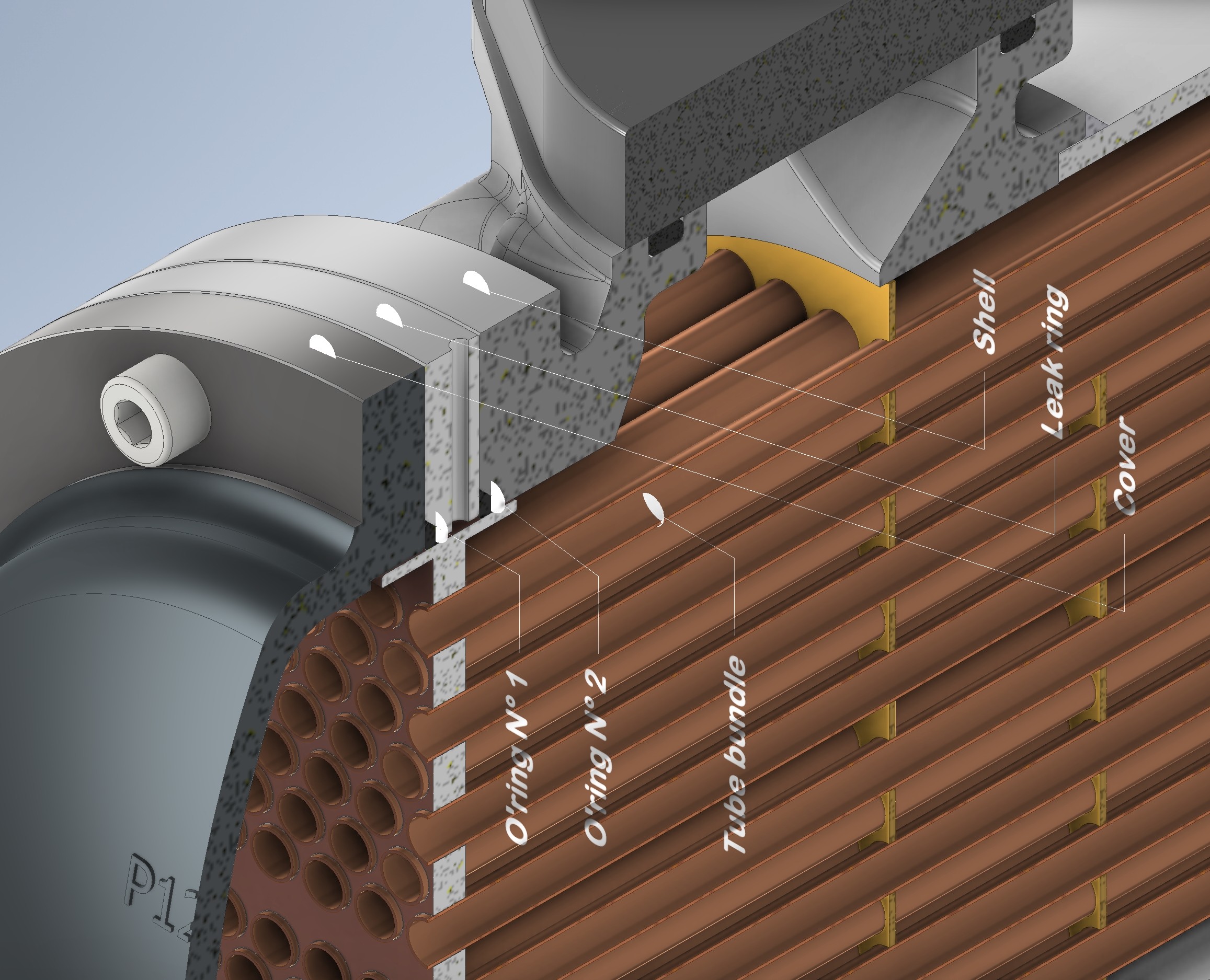

The majority of the PICKER heat exchangers are equipped with a double O ring of sealing between tube bundle and element, side plate-tubular “slipping” (cf diagram hereafter).

The addition of a bored intercalated ring playing the part of “witness of escape” authorizes a setting with the free air of the fluid released in the event of deterioration of the one of these joints and thus avoids any risk of accidental mixture of the two involved fluids.

FIXATION OF THE APPARATUSES

The PICKER heat exchangers are established on the installation by means of two mounting feet with tapped holes, integrated origin in the foundry of the element. The PICKER heat exchangers can be installed indifferently vertically or horizontally, and in the latter case, on the ground, “on the ground the ceiling” or “on the ground the wall”.